Helically Loaded Magnetic Loop Antenna

Object of the design:

There are

many designs and information available on the net concerning “Magnetic Loop Antennas”.

Even though

these antennas are a fraction of the size of a full size resonant antenna, size

of the lower frequency loop can still be quite large for a limited sized property.

The object of my design is to compact the size of a magnetic loop while trying

to maintain the efficiency of the loop.

Theory of Design:

Anyone that

has delved into the theory of magnetic loops knows that smaller size loops

result in very poor efficiency at lower frequencies. A magnetic loop for the 80

meter band should be 15 ft diameter to produce efficiency of 88%. Using a 3”

diameter copper pipe at a 15 ft diameter will only produce a 7Khz band width.

This band width requires very precise tuning.

By

implementing a helically wound design a 6ft diameter 80 meter text book loop seems

to emulate a 10 to 15 ft diameter loop

of a single conductor. The 80 meter bandwidth of my 6 ft loop is 11Khz. The

loop construction technique provides for light weight and cost as compared to a

15 ft loop constructed from copper tubing. This design has been accomplished by

using just enough copper to take advantage of “Skin Effect”. This allows the use of a thin flat copper conductor

which provides more surface area then a heavy copper pipe while still providing

a large surface area of RF skin depth. At the same time the radiation resistance is

raised considerably while only raising the IR losses slightly. The ratio of

Radiation Resistance to IR losses equals the efficiency. The use of PVC tubing and flat soft copper

strap provides a sturdy substrate in which to wrap the soft copper strap while

increasing inductance for the same circumference as a substantially larger loop.

The result is a two part gain; the same length of copper conductor that is

required for a 10 ft diameter loop equates to similar performance wound on a 6

ft diameter substrate; thus reducing the size, weight and cost while still

retaining the performance. These miniature

loops for bands as low as 80 meters have now become such a small footprint that

they can be employed in an HOA situation even if hidden between foliage. There

are still a few factors that I have not calculated yet. The use of loading and

the distributed capacitance somewhat adds a mysterious factor to this design. I

am still working out all the details. The apparent efficiency and the large

increase in Band Width tell the story. My actual “on the air testing” has

depicted better results than I could have imagined. So far my “seat of the

pants measurements” has shown a great increase in the tightness of the doughnut

pattern shape. The approximate 4 degree very sharp null I am seeing to near E

field noise seems much tighter then my previous single conductor loops. I have

also noticed from many signal reports that I am experiencing as much as 3 to 4

S-units increase/decrease in signal strength by rotating the antenna with

distant stations. This seems to be more apparent depending on the angle of

radiation being utilized at the time of contact. There may possibly be more

horizontal radiation off the side then a normal single conductor loop; this is

just theory for explanation at this point. The reason that I am theorizing the

polarization is due to the fact that I have seen stations get much stronger

broadside while I other stations get much stronger in the plane of the loop.

Text book magnetic loop theory states stronger in the plane of the loop. This

is definitely the case for ground wave stations; I have tested this in depth

with great repeatability. I can get a 3 to 4 S unit change at 20 miles on the

20 meter band, the signal will just about completely null broadside to the

loop.

Details of building

this design:

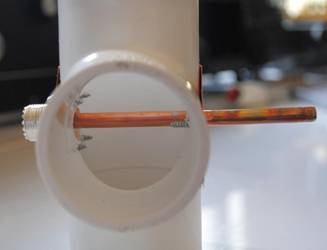

The Hi-Res

photos that I am attaching to this article will depict more than can be described,

thus I will not go into great detail.

Starting

with the PVC octagon frame, calculate your PVC parts by the size of the loop

desired for the particular frequency range. View my photos carefully to observe

how to mount the SO-239 connector; do this before gluing any frame parts.

Use a hard temper piece of copper flashing for

the underlay of the SO-239 connector. Soldering this connector as the photo

shows is important. The photo also depicts how the center feed from the SO-239

was routed thru the PVC- T. Finish this part carefully before any gluing. Use a

short length of ¼ inch copper tubing to follow thru the PVC T for stability of

the connection. If this connection breaks after gluing the frame you will be in

trouble! Fill the short length of tubing

with solder then heat it a push it over the center conductor of the SO-239 and

heat generously. The other exiting end out of the PVC T will then be supported

by the T itself, this makes for a very strong connection point.

Use cleaner

and good glue and glue the frame together, use ingenuity when assembling the

frame as to what parts to glue first. Once the part is glued and it isn’t right

it will be very difficult to correct.

Make sure to

use both good quality PVC cleaner and Cement for good bond which will provide stability

of the frame. The frame will need about 3 coats of high quality Krylon spray

paint. I use flat black as it hides well, Krylon makes a spray paint for

plastics; this is the one that I recommend.

If you do not paint the frame the PVC will deteriorate fast especially

in the western state where I am located. The next generation of prototype will

use a plastic protective paint on the substrate and a clear lacquer coating

over the copper for corrosive protection.

Now it’s

time to wrap the frame, this part is a bit tricky the first time you do it. The

rule that used to build both prototype loops was adding 37.5 % of conductor

length to the amount of conductor required for a single turn loop. Credit is given here to “AA5TB” the work on a great loop

calculator. AA5TB calculator has been very useful to speed up calculations, I

have compared it to hand calculations, it is very exact; just search the net

for his Excel program. Plug in all the factors for the loop that you want to

build and follow my rule for length of conductor. Use the width of the copper strap X2 in place

of the circumference (diameter X 3.14) the formula requires diameter. Divide

the calculated length of the conductor in half, and mark the center of the

length. Start the wrapping at the marked center at the SO-239, pay close attention

to the pitch of the material. Again some ingenuity on calculating the wrap

spacing is necessary here. Make sure

that the two ends of the material come out even at the capacitor/tuner feed

point. If care is not taken here you will have an unbalanced loop. Once the

loop is wrapped and if it came out even, then temporarily tape the ends in

place while you solder the center of the flashing very carefully to the so-239

supporting foil.

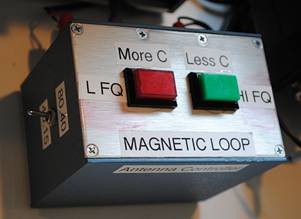

Capacitor & Drive

Motor Assy:

The tuning

capacitor is one of the most critical devices in this build project. Choosing to use anything but a good quality

vacuum variable capacitor will result in substandard performance compared to

the results claimed in this prototype antenna. First issue is power handling, my loops handle

SSB full legal limit (1500wts), and are rarely run at more than 1Kw. To keep the Q high and power capability high

use a vacuum cap otherwise the results will probably be disappointing. Humidity

will also play a role in affecting your antenna by using an air capacitor. I am using a 12 volt gear reduction motor

with a forward and reverse controller arrangement. The down side is the long

times required to change bands. The reductions need to be slow for precise

tuning, thus a single speed geared motor is not the best solution. My next

prototypes will utilize a stepper motor control system which is currently in

development. Utilizing a stepper motor control in conjunction with a PIC or other

small processor board the speed can be controlled enabling quick band changes, and

then use a system of fine tuning buttons to move about the band of operation.

Tuning unit mounted in the

operating position.

Great care

must be taken with all connections; every milli-ohm gets multiplied in the main

conductor will be subtracted from the total radiated power. This results in

lower antenna efficiency. All overlapping

joints in were tinned on the underside, and then quickly heated with a torch.

After cooling they were all soldered using a very hot iron all around the copper

edges. Try not to leave any sharp edges, there can be 15 KV at the area around

the capacitor connection; some corona arching could happen at sharp points.

The Gamma Match:

Several

different matching techniques have been tried, most worked although negligible

difference was noticed using the simple gamma match. The gamma match also seems

to be the flattest match across the entire tuning range. Once tuned to the center

of the tuning range of the loop design the match appears to hold a flat match

of < 1.2 to 1 @ 50 ohms across the range. It will be the farthest off at the

lowest band. It takes a bit of

experimentation to get it perfect. Both loops are 1:1 @ 50 ohms except on the

lowest designed band; there it may be 1.2 or 1.3 which is negligible.

If you tune

your loop in the horizontal position, do not solder it in place until you mount

it in the operating position complete vertical plane. Just use a SS hose clamp

fastener to get the match, when you are satisfied then solder it to the foil

and clamp over it to keep it secure. The 80/40 meter match proved to be twice

as long until I mounted it in the vertical operating position.

Match was 1:1 @ 50 ohms

here, DO NOT SOLDER YET!

Rear view of gamma

match in operating position, indicating how the SO-239 connection exits from

the rear of the PVC T

Front view of gamma

match soldered in place; 1:1 @ 50 ohms

More photos of

construction in progress

Gamma Match – 20 thru 10 meter loop

Gamma Match – 20 thru 10 meter loop

20 thru 10 meter loop

under construction, this one will be painted after finished

Loop Controller,

controls both loops with side switch

Finished 20 thru 10

meter loop ….. Just needs paint

Parts list

Copper foil/flashing: 3 inches wide X .008

thick (8 mils), Soft anneal.

Less than 8

mils will cause heat loss resulting in poor efficiency. Efficiency is the ratio

of Radiation Resistance to IR losses. Material that has a large RF Skin area is

required while still thick enough to handle VERY LARGE circulating

currents. Unfortunately this is hard to

find and very expensive in small quantities. I have found that suppliers do not

want to deal in the lengths required. I

have had to purchase large quantities of this material to get cost effective.

Please email me if you need options for the copper flashing.

K8NDS@HLMAGNETICLOOPANTENNAS.COM is not longer active

PVC:

2 inch schedule 40 PVC has approx 2.25 inch OD.

This size is required for the 80/30 meter version. The diameter is required to achieve the

necessary inductance of the overall loop diameter.

Vacuum Capacitor: At least a range of

10 pf to 250.

If you use

the loop formula it will indicate that you need more “C” but the helical

winding brings that capacitor value down. To be safe I would purchase 10/300pf version. A 10

to 500 pf version could be utilized in case you might want a larger cap for future

development. More precise control will

be realized with the 10/300pf using my helical wound design. The ratio of

capacitance to the gear ratio of capacitance to turns will smooth out fine

tuning. The

voltage rating should be 15 KV @ at least 40 to 50 amps. Many of the Vacuum Capacitors especially

surplus units are drastically under rated. Some are capable of double the

posted rating. Check this out with the

supplier. 15 kV is possible across this

capacitor running 1KW. If a 25 KV

version can be located, it would be the best choice. The SSB or CW modes and

respective duty cycles actually allow the use of smaller KV values. If you plan

on running key down, AM or high power digital modes you may want to reduce your

power output to 500 watts continuous.

Tuner Mounting Board: An inexpensive easy to purchase material is a

cutting board from Walmart. About 7 to 8

dollars can buy a durable cutting board that is a very good insulator (White/opaque)

in color. It can easily be cut down to size to mount the motor/drive system and

capacitor.

Capacitor Clamps: Use some ingenuity

here depending on the type of Vacuum cap that you acquire. As can be seen in my

photos electrical conduit clamps are used on one unit. Care must be taken that

the clamps are very tight and making a very positive connection; the use of copper

flashing in between the clamps and the cap just to make sure.

Drive System: In viewing my photos it can be seen that a geared 12 volt DC

motor, reversible. If this your choice a means of keeping track of position in the

range of the capacitor is necessary, if care is not implemented here you will

either jam the cap to one end or unscrew the shaft at the other end depending

on the cap construction. Utilizing

ingenuity/design limit switches can be employed in the control circuit. There

are Magnetic loop sites on the net which have accomplished this method. I just keep track of the band of operation, I

have never dead ended the system yet but that is me; this is not the recommended

way to travel. This was my prototype version; I am currently working on stepper

motor controls for fast and precise tuning. Keep in touch with my web site and

I will post updates.

SO 239: Pay attention to my instruction and photos on how to mount

the SO-239, once the PVC is glued together it will be difficult to repair.

Radiating the

Cows! Hi Hi……….

Radiating the

Cows! Hi Hi……….

The author/ Designer Rich

K8NDS

Thank You for reading

the article.

I hope that you have as

much fun with these stealth antennas as I have had. It is a way for the HOA

restricted Amateur operator to come very close to the performance of full size

antennas.

Please look me up if

you want to see these antennas in action, I think you will be quite surprised

at the functionality of these small antennas. Many on the bands have heard

these already and have stated how good the signals were………… in amazement!

You can find me

whenever I am active on the bands by visiting

QRZ.com and look up K8NDS

Then just click on “MY QSX” link

It will take you to my

page where you can see what frequency that I am talking/listening on. Many have

already done this. You can also view your own signal strength there while you

are transmitting.